Project for Mass-Production and Export of Pure Hydrogen, Oxygen, Hydrogen-Hybrid Fuel (MOH Gas)

and various H2-based Systems, with Off-Peak Power,

produced by Nuclear, Solar, Wind, Hydro, Coal, NG, etc. Fossill-Fuel Power Plants.

Such a production could take place near the 100% Government-owned "Kozloduy" Nuclear Power Plant (NPP) in Bulgaria, http://www.kznpp.org/index.php?lang=en ,

using unlimited water resource from the nearby-running Danube River, and the cheap night / off-peak Electric Energy produced by both 1000-Megawatt (1GW each) Reactors of the Power Plant, for which there is very low or no consumption during the nighttime and a lot of the power produced just wastes along the power grid.

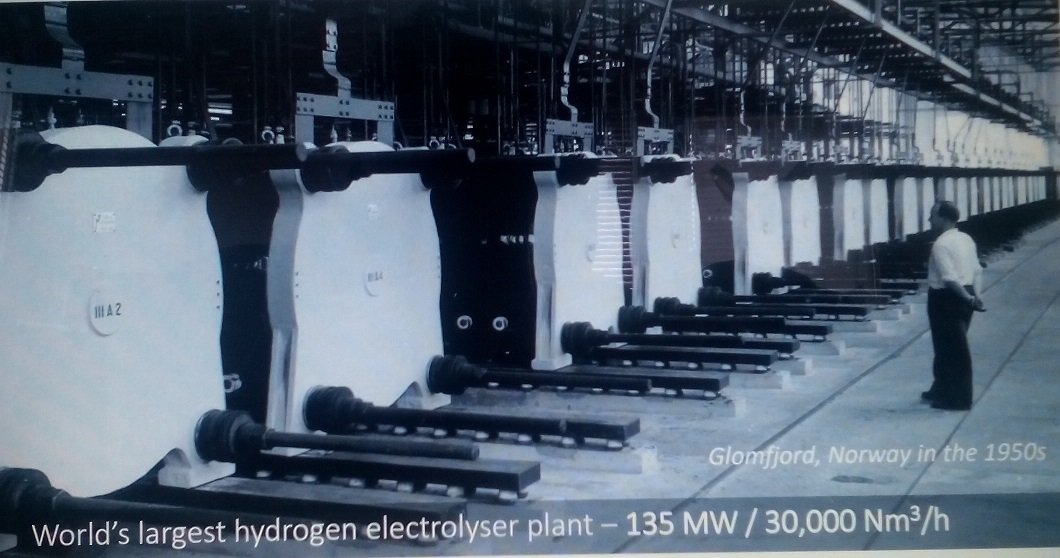

Using the technology we have available, for Low-Power (12.3 kWh / kg H2) Water Electrolysis (LPWE), - https://fuels.alle.bg , or other similar technology, it's possible to produce over 150 metric tons per hour of 100% pure Hydrogen.

This hydrogen could be offered for export sales across the world, at the average market prices ( $10/kg in USA, GBP12/kg in UK) which would generate gross revenues of about $ 1,500,000 (a million and half US Dollars) per HOUR .

Production of clean fuels appears to be about 50 times more profitable than producing power.

What's more, construction and commissioning of both new 1000 MW Reactor Units of the new "Belene" NPP located near by, will double this revenue.

Belene NPP Project actually includes total of FOUR reactors of 1000 MW each, and there is a permission for additional 2 reactors 1GW each to be placed on the NPP Kozloduy's site.

World's consumption of hydrogen for 2018 was about 60 million metric tons (726 billion cubic meters) . Over 99% of this hydrogen is produced by reforming fossil natural gas, i.e. in an ecologically "dirty" way, while in our case we are talking about 100% clean, electrolysis-grade production.

World's Oxygen demand for 2018 was more than 350 Million metric tons.

MODIFED OXYGEN-HYDROGEN (MOH) STOICHIOMETRIC GAS COMPOSITION

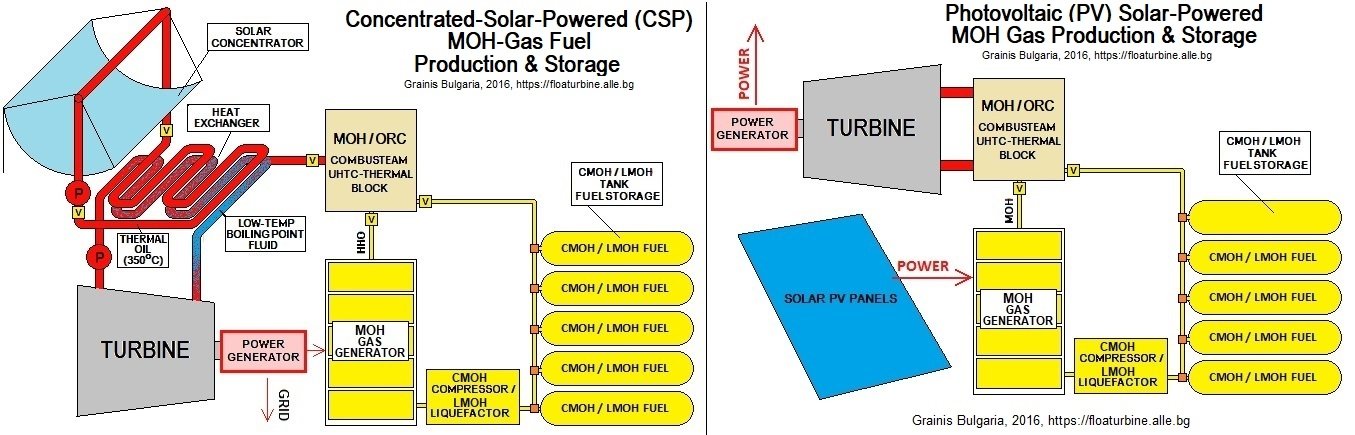

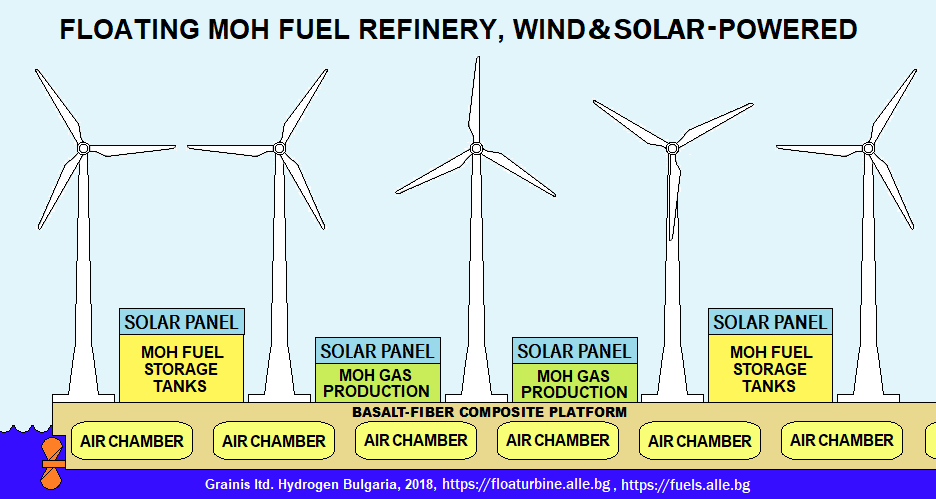

Production, based on the above-mentioned technology, of Universal, 100% Clean and Renewable Hybrid-Hydrogen MOH Gas ( patented in 2008/2011 in Japan as Ohmasa Gas), would bring much more revenue.

http://www.patentsencyclopedia.com/app/20110139630#ixzz3LOxSiPwy

https://www.youtube.com/watch?v=NUPE0Z9V82E

In addition, the MOH Gas can be used as a 100% fossil-fuel substitute for Gasoline internal-combustion Engines, and can be 100% pressurized, pumped and safely transported along the existing Bulgarian Natural-Gas Pipeline Network, just like the Natural gas, liquefied or compressed. https://fuels.alle.bg

MOH could be also burned by special Zirconia burners in Steam Boilers, Furnaces and more thermal installations.

All the Coal and else Fossil-Fuel-Fired Power Plants could be converted not only to burn, but also to produce MOH Gas - https://coal-to-gas.alle.bg

A MOH Gas Refinery installation could also be built near the large underground Gas Storage Facility in the village of Chiren, etc., where huge quantities of MOH can be stored as a reserve.

Compressed or Liquefied MOH Gas is the best Hydrogen, Oxygen, and Clean Fuel / Extra-Energy Storage.

One m3 of liquid MOH contains 167kg of Hydrogen, while 1m3 of liquid Hydrogen alone, contains 70kg Hydrogen only, or MOH is 2.5 times denser.

Also, MOH is much safer ( can't be ignited by a spark, doesn't perform leakages, permeation, diffusion and embrittlement, as the H2 ), and is 100 times cheaper ($0.10/kg MOH vs $10/kg H2).

Mass-production of Hydrogen, Oxygen, and Hybrid-Hydrogen SOH and MOH gas fuels will offer an additional opportunity for starting mass production of H2 and Hybrid-Hydrogen-based Systems as H2-Engines, Gas Turbines, Lift-Power Aerostatic Systems, Stratospheric and Aerospace Craft and Systems, Basalt-Fiber Structural Composites, Defense Products, Hydrocarbons & Polymers, Ammonia-Based Fuels and Chemicals, etc.

Grainis ltd. Hydrogen Bulgaria ,

5 Gen. Edward Totleben blvd., 1606 Sofia, Bulgaria,

tel. +359 899 171570 (En, 9AM-10PM EET) ,

grainis@abv.bg, grainisbg@gmail.com,

https://fuels.alle.bg